Project Overview

About this Project: The Problem & Solution

The LYKA Lamp is the world's first fully integrated consumer product powered by Microbial Fuel Cells (MFCs) that utilize household compost. It addresses the dual problems of energy scarcity (770 million people globally lack electricity) and the environmental burden of organic waste by creating a reliable, low-cost lighting source.

Through systematic optimization, I achieved a sustained power output sufficient to run a 9V LED bulb for 2.43 hours of continuous light after charging. The system requires only compost (organic waste) and a $16 investment to provide renewable, off-grid power.

Key Performance Metrics

- Optimal Output: 1.73 Watts (Achieved under optimal 12–18 month compost, Carbon Cloth, 1cm spacing).

- Energy Independence: 11.95 hours required to fully charge the battery for max runtime.

- Economic Benefit: Average U.S. family saves $128.76 annually on energy costs.

- Environmental ROI: Prevents 45,000 lbs of CO2-equivalent emissions per family annually.

Core Materials & Components

- Containment: 3D-printed ABS filament housing.

- Electrodes: Optimized Carbon Cloth and Copper Wire.

- Electronics: LM2596 Buck Power Convertor, TP4056 Charger Module.

Product Prototype

Figure 1: The final product prototype (Test 3 construction).

Circuit Detail

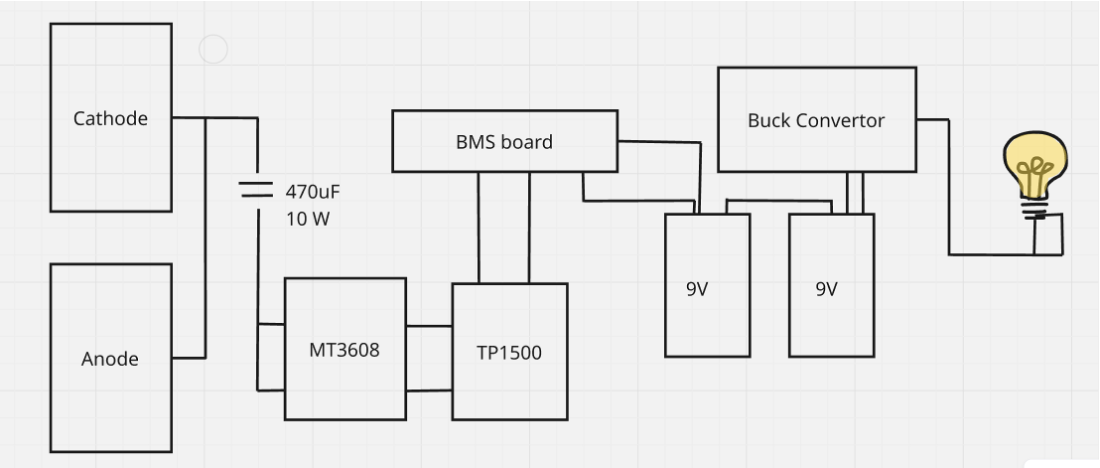

Figure 2: Custom DC Step-up Converter and PCB that harvest and store power.

The Energy

- Energy Source: Anode Chamber where microbes decompose organic waste, releasing electrons ($\text{e}^-$).

- Harvesting Layer: Electrons are collected by Carbon Cloth electrodes and directed to the custom circuit.

- Conversion Layer: LM2596 Buck Convertor regulates and steps up the low, variable voltage/current.

- Persistence Layer: TP4056 Charger Module safely stores energy in the rechargeable battery.

- Presentation Layer: Stable power is delivered to the 9V LED Lightbulb.

The Engineering

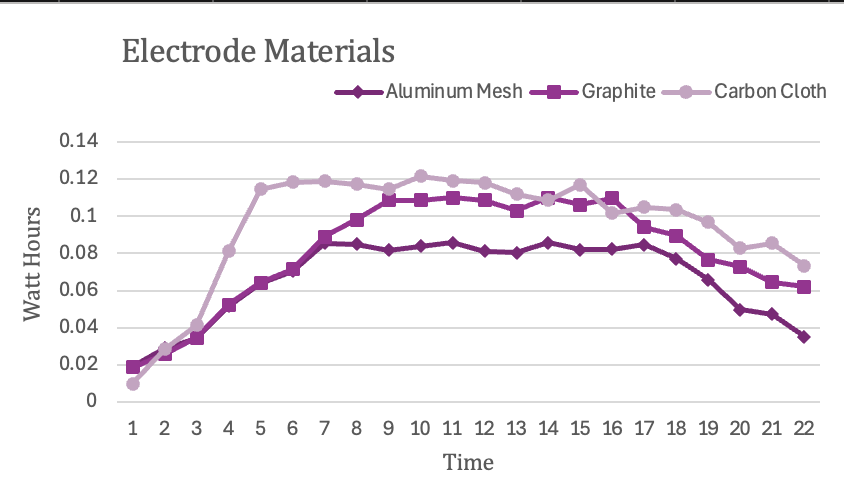

1. Optimization Testing

Systematically tested variables: Compost Age, Electrode Material, and Container Volume. Identified the optimal combination (12–18 month compost, Carbon Cloth) necessary to achieve maximum power density (1.73 Watts).

Figure 4: graphs showing variability in different materials for microbial fuel cells.

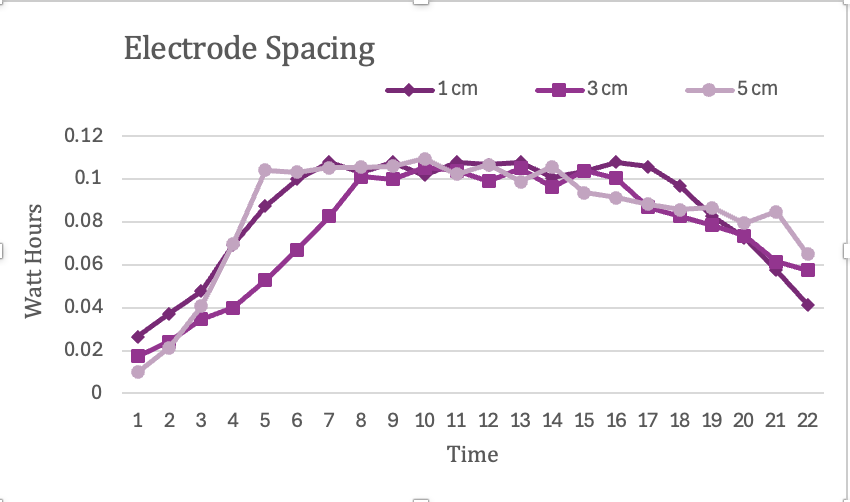

2. Spacing Refinement (Test 2)

Refined the Electrode Spacing to 1 cm, which was the ideal distance for efficient proton transfer and resistance minimization. The final 3D-printed modular design was built to guarantee this exact spacing.

Figure 5: 3D-printed modular structures ensuring precise 1 cm electrode spacing.

3. Final System Construction (Test 3)

Integrated the optimized MFC into the custom 3D-printed housing and constructed the DC Step-up Converter circuit to successfully power the 9V LED lightbulb, proving the system's practical feasibility.

Impact

The LYKA Lamp benefits society by addressing energy scarcity, mitigating climate change, and providing economic utility.

- Economic Utility: An average U.S. family can save $128.76 annually. Widespread adoption could yield $12 billion in national energy savings yearly.

- Global Accessibility: Provides a sustainable, low-cost lighting solution for the 770 Million+ individuals globally who lack access to conventional electricity.

- Environmental Impact: Offsets organic waste, which would otherwise release greenhouse gases. Scaling to 50% U.S. adoption could offset over 409 Million Metric Tons of CO2 emissions annually.